WATERLOO BARRIER® CUTOFF WALL

-

Waterloo Barrier® is a low permeability cutoff wall for groundwater containment and control. It is a design of steel sheet piling featuring joints that can be sealed after the sheets have been driven into the ground. The product was developed by researchers at the University of Waterloo (UW) and has been used at over 100 sites in North America. C3 Environmental assisted in the development and commercialization of the product and is currently the exclusive licensed installer for the system. Field tests confirm that Waterloo Barrier® is an effective method for providing low bulk hydraulic conductivity containment of ground water in subsurface soil environments.

-

Low permeability containment walls are increasingly being applied in the control and remediation of groundwater pollution. Conventional technologies such as slurry walls and geomembranes do not necessarily provide cost-effective and efficient subsurface containment in all settings. Groundwater researchers at UW considered this in their construction of containment cells for field experiments involving contaminated groundwater.

-

The concept of driving steel sheet piling and sealing joints between adjacent piles was thus introduced. After a series of successful experimental cells, the potential utilization of Waterloo Barrier® in real site conditions was confirmed with approximately one year of prototype field testing. UW and Samuel Roll Form Group then collaborated to develop sheet piling in which a sealable cavity was incorporated into the pile interlock in the manufacturing process. A roll-formed shape was produced and made available for field trials in 1991. Extensive field scale tests were conducted by UW, and bulk hydraulic conductivity values of less than 10^-8 cm/sec were achieved. Installations of a commercial nature are currently in service.

-

Check out some Case Histories Here

Deep, enclosing barriers around hazardous waste sites or municipal landfills.

Shallow, enclosing barriers to contain petroleum products or other light contaminants which float at the water table.

Shallow or deep enclosures to control future groundwater contamination at new industrial or waste disposal sites.

Temporary, enclosing barriers to facilitate various removal or in situ remediation procedures.

Barriers along shorelines to prevent seepage of contaminated groundwater into waterways.

Isolation of accidental spills.

Cofferdams in waterways to facilitate efficient dewatering procedures. Funneling or directing contaminated plumes to enhance the efficiency of pump-and-treat techniques.

Groundwater control in construction projects involving excavating and tunneling.

-

Rapid installation and sealing.

Minimal disturbance of site during construction.

Easily adapted to irregular layouts.

Limited site access less of a problem compared to alternative cutoff wall techniques.

Easily installed in areas with high water tables and surface water.

Easy to inspect and monitor for superior quality assurance and control during construction.

Predictable hydraulic performance.

Positive public perception.

Long service life for permanent installations.

Can be easily removed where applications are temporary.

-

Waterloo Barrier® sheet piles are installed using the same equipment and techniques as conventional products. Vibratory equipment is suitable for most soil conditions although better results may be achieved with impact equipment in certain cohesive soils.

Pile lengths of up to 70 feet are available and for greater depths, the piles can be spliced. Corners and special fabrications are available for any geometric layout. A footplate at the toe of each larger interlock prevents larger rocks and most of the soil from entering the sealable cavity during driving.

After driving, the cavities are water jetted to remove the small amounts of loose soil and prepare for the injection of sealant.

C3 Environmental specifically develops several types of grouts including polymer, clay, and cementitious based grouts to seal the interlocks of the Waterloo Barrier® sheet piles. These grouts are designed to provide resistance to the wide range of chemical constituents and site conditions.

-

Potential leak paths through the Barrier are limited to the sealed joints. Therefore, the joints are the focus of the quality control procedures. Joints are inspected before the sealing operation to confirm that the complete length of the cavity is open and can be sealed. Video inspection equipment can be lowered into each clean cavity to provide a permanent visual record. Each joint is sealed from bottom to top facilitating the emplacement of sealant into the entire length of the joint. Proven procedures can be initiated to clear identified blockages within the interlocks prior to the sealing process. C3 provides trained inspectors to perform the quality assurance and control during the sheet pile installation and interlock sealing phases. The Quality Assurance and Control program is rigorous and unique to the Waterloo Barrier® and is an integral part of our certification of the system.

-

The Waterloo Barrier Cutoff Wall was developed through years of intensive testing and has been the cornerstone of remediation programs on over 100 sites across Canada and the United States. Discover more about how the Waterloo Barrier has become the go-to technology for environmental subsurface containment.

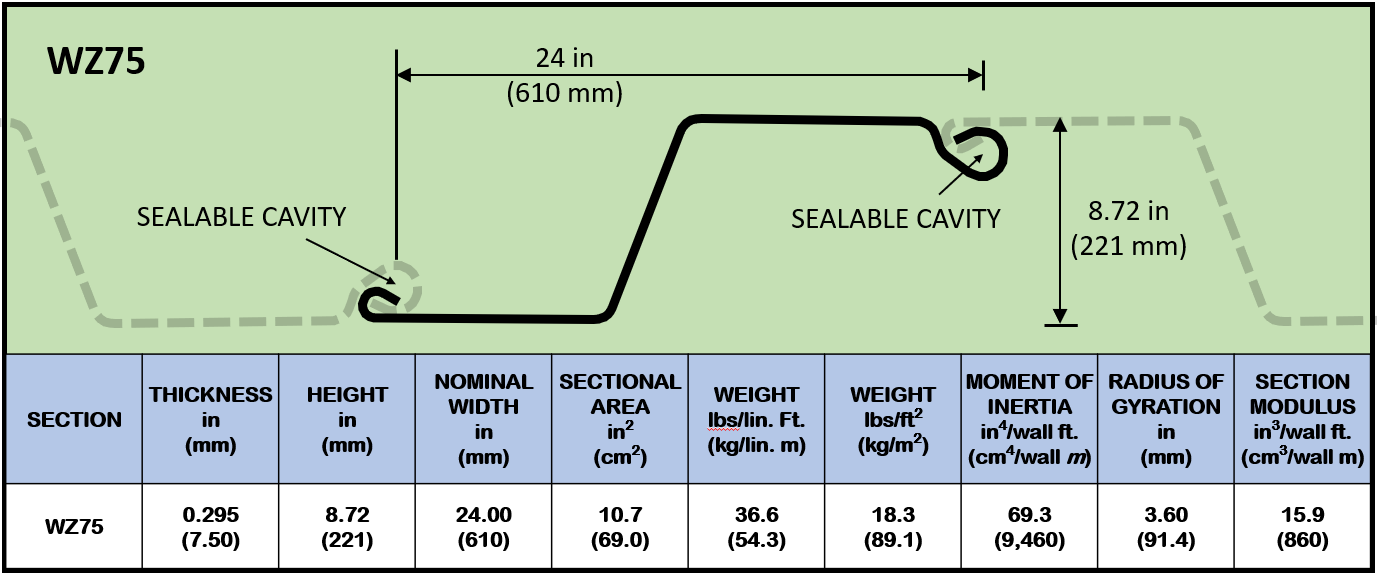

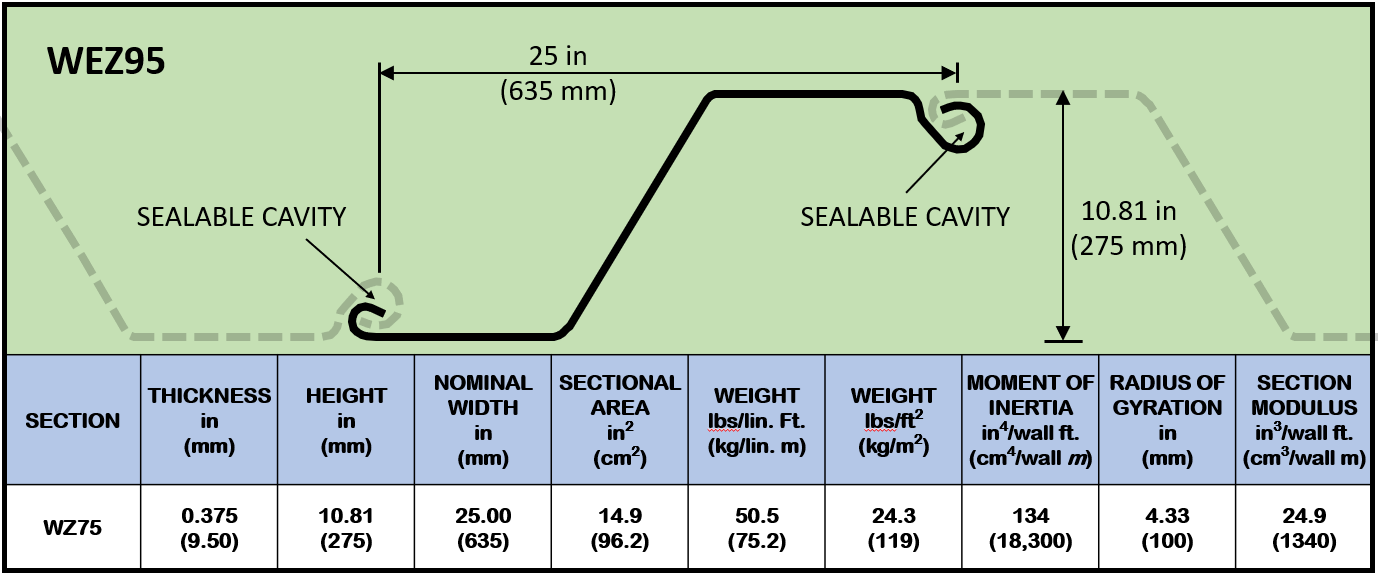

The Waterloo Barrier is available in 2 designs and thicknesses.

C3 environmental will help you determine which design is best for your project needs according to the relevant soil conditions.

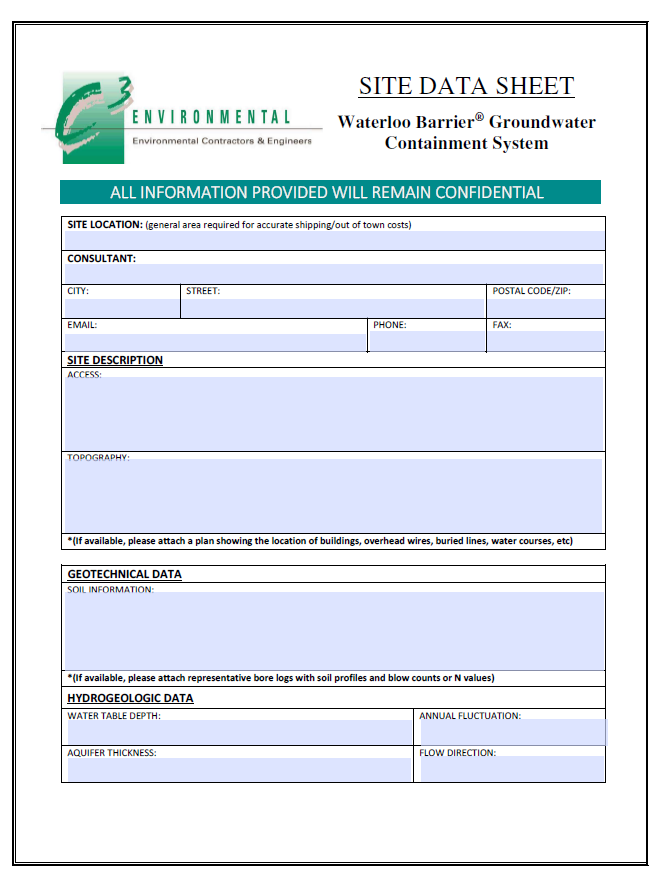

Do You Have an Upcoming Project?

Thinking about using the Waterloo Barrier in an upcoming project?

Fill out a Site Data Sheet and email it to c3environmental@c3group.com for a quote!